| Common Thickness For Reference | ||||

| Thickness(mm) | Tolerance (mm) | Weight(kg/pc) | Tolerance(kg) | MOQ(20GP/pcs) |

| 1.3mm | +-0.05 | 8.0kg/pc | +-0.5 | 3000pcs |

| 1.5mm | +-0.05 | 8.2kg/pc | +-0.5 | 2700pcs |

| 2.0mm | +-0.05 | 12.3kg/pc | +-0.5 | 2000pcs |

| 2.5mm | +-0.05 | 15.3kg/pc | +-0.5 | 1600pcs |

| 2.8mm | +-0.05 | 17.2kg/pc | +-0.5 | 1400pcs |

| 3.0mm | +-0.05 | 18.4kg/pc | +-0.5 | 1300pcs |

| 3.2mm | +-0.05 | 19.6kg/pc | +-0.5 | 1250pcs |

| 3.5mm | +-0.05 | 21.5kg/pc | +-0.5 | 1150pcs |

| 4.0mm | +-0.05 | 24.5kg/pc | +-0.5 | 1000pcs |

| 5.0mm | +-0.05 | 30.7kg/pc | +-0.5 | 800pcs |

| 6.0mm | +-0.05 | 36.8kg/pc | +-0.5 | 650pcs |

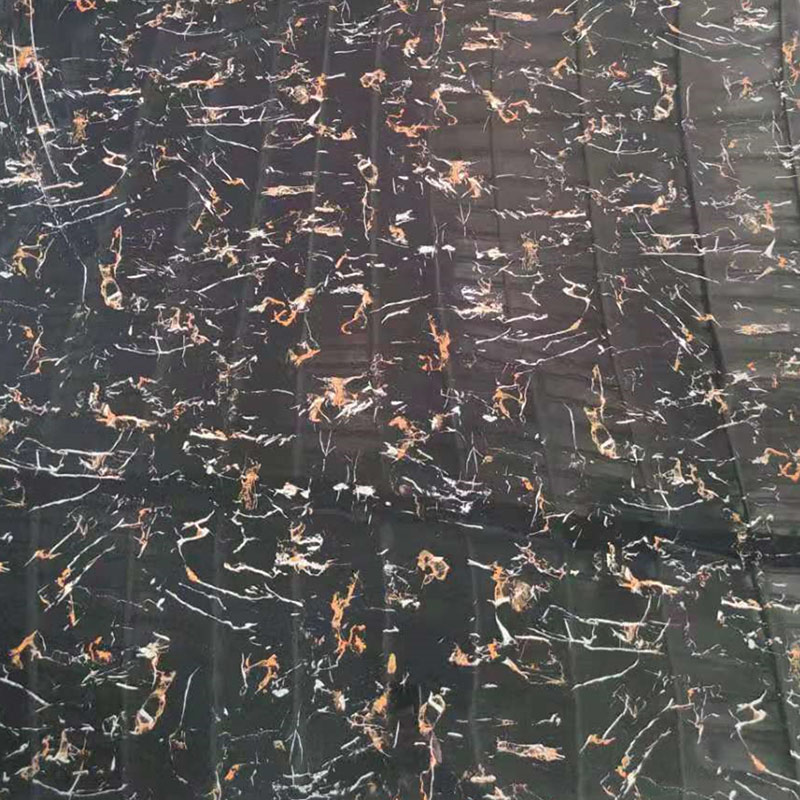

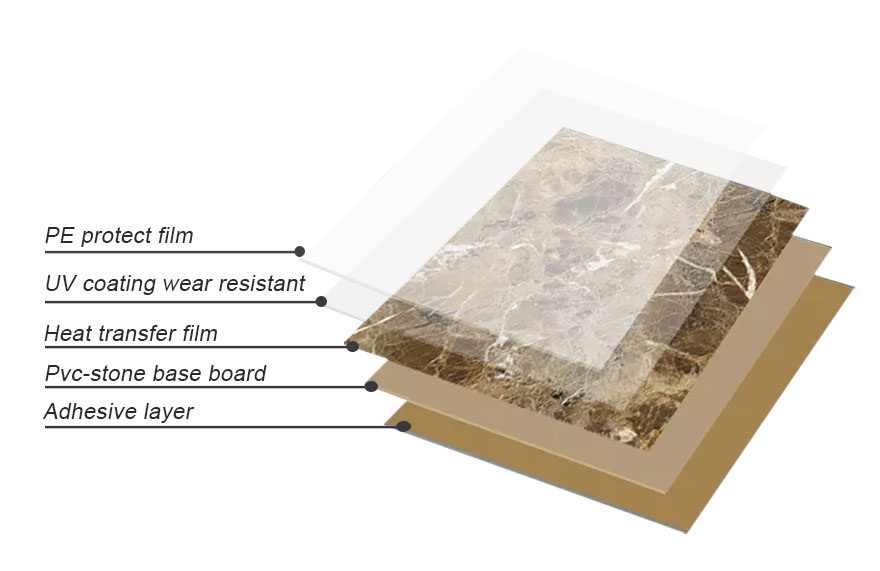

UV PVC Wall Plank is a sheets whose surface is protected by UV treatment. UV paint is ultraviolet curing paint, also known as photoinitiated paint. PVC, wpc, spc and other boards are formed by applying UV paint and then drying through a UV curing machine. Because of their easy processing, industrial production can be realized, with bright color, abrasion resistance, strong chemical resistance, and long service life. High mechanical equipment and process technology requirements, and have the characteristics of resistance to moisture and deformation: the primer adopts a solvent-free 4E green high-grade paint, which is non-volatile, non-toxic and environmentally friendly; it has a high gloss antibacterial effect after curing, which is an ideal decorative board . Production Process : 1. Material selection Pvc wall plank → 2. The bottom of the board is sprayed with a transparent sealing layer → 3. Repair → 4. The board is sprayed with the first layer of primer → 5. UV light curing → 6. Polished → 7. The board is sprayed Two-layer primer → 8. UV light curing → 9. sanding → 10. spraying the first top coat → 11. UV light curing → 12. sanding → 13. spraying the second layer paint → 14. UV light curing → 15 .Grinding→16. Coating the third top coat→17. UV curing→18. Inspection and acceptance→19. Packing protective film. Characteristic : A: High surface smoothness: the mirror highlight effect is obvious. B: The paint film is plump: the color is plump and attractive. C: Environmental protection and health: Generally, the baking finish of the baking varnish type board is not good, and volatile substances (VOC) are constantly released. UV wall sheets solve the problem of environmental protection in the century. Not only does it contain no volatile substances such as benzene, but it is cured by ultraviolet light to form a dense cured film, which reduces the amount of substrate gas released. D: No fading: Through comparative experiments, it is proved that UV decorative panels have better physical and chemical properties than traditional panels, ensuring that the UV panels will not lose color for a long time, and solve the phenomenon of chromatic aberration. E: Scratch resistance: the higher the hardness, the brighter it is, and it will not be deformed for a long time after curing at room temperature. F: Acid and alkali resistance and corrosion resistance: UV panels can resist the corrosion of various acid and alkali disinfectants. The reason for the formation of the above characteristics of the UV board is that the chemical reaction between the paint and the ultraviolet rays forms a dense protective film. The distance between the molecules of this dense protective film is very small, which is smaller than that of water molecules and acetic acid molecules. It has the effects of waterproof and stain resistance. However, the white UV panel is easy to turn yellow when exposed to sunlight, and the industry cannot solve this problem.

UV PVC Wall Plank is a sheets whose surface is protected by UV treatment. UV paint is ultraviolet curing paint, also known as photoinitiated paint. PVC, wpc, spc and other boards are formed by applying UV paint and then drying through a UV curing machine. Because of their easy processing, industrial production can be realized, with bright color, abrasion resistance, strong chemical resistance, and long service life. High mechanical equipment and process technology requirements, and have the characteristics of resistance to moisture and deformation: the primer adopts a solvent-free 4E green high-grade paint, which is non-volatile, non-toxic and environmentally friendly; it has a high gloss antibacterial effect after curing, which is an ideal decorative board . Production Process : 1. Material selection Pvc wall plank → 2. The bottom of the board is sprayed with a transparent sealing layer → 3. Repair → 4. The board is sprayed with the first layer of primer → 5. UV light curing → 6. Polished → 7. The board is sprayed Two-layer primer → 8. UV light curing → 9. sanding → 10. spraying the first top coat → 11. UV light curing → 12. sanding → 13. spraying the second layer paint → 14. UV light curing → 15 .Grinding→16. Coating the third top coat→17. UV curing→18. Inspection and acceptance→19. Packing protective film. Characteristic : A: High surface smoothness: the mirror highlight effect is obvious. B: The paint film is plump: the color is plump and attractive. C: Environmental protection and health: Generally, the baking finish of the baking varnish type board is not good, and volatile substances (VOC) are constantly released. UV wall sheets solve the problem of environmental protection in the century. Not only does it contain no volatile substances such as benzene, but it is cured by ultraviolet light to form a dense cured film, which reduces the amount of substrate gas released. D: No fading: Through comparative experiments, it is proved that UV decorative panels have better physical and chemical properties than traditional panels, ensuring that the UV panels will not lose color for a long time, and solve the phenomenon of chromatic aberration. E: Scratch resistance: the higher the hardness, the brighter it is, and it will not be deformed for a long time after curing at room temperature. F: Acid and alkali resistance and corrosion resistance: UV panels can resist the corrosion of various acid and alkali disinfectants. The reason for the formation of the above characteristics of the UV board is that the chemical reaction between the paint and the ultraviolet rays forms a dense protective film. The distance between the molecules of this dense protective film is very small, which is smaller than that of water molecules and acetic acid molecules. It has the effects of waterproof and stain resistance. However, the white UV panel is easy to turn yellow when exposed to sunlight, and the industry cannot solve this problem.| Dimension | Name | UV SPC SHEET or SPC SINTERED STONE |

| Material | 42%PVC resin+55%Calcium+3%Additive Composite | |

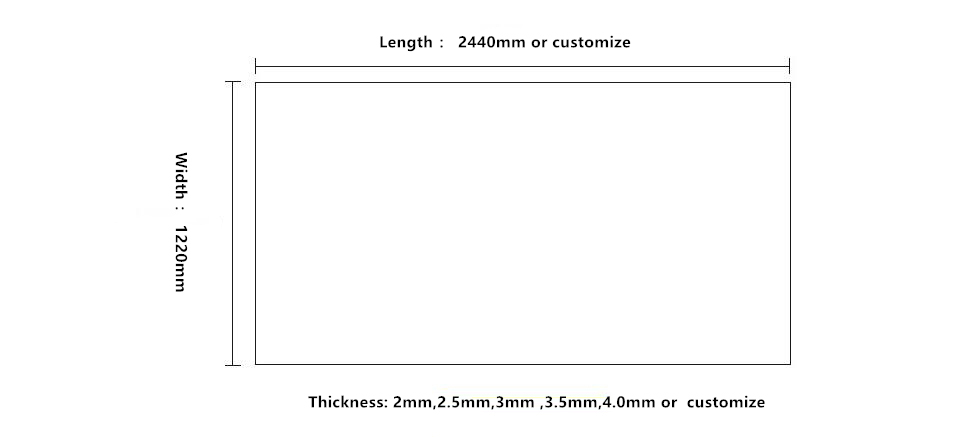

| Size | 4X8FT (1220*2440mm) | |

| Thickness | 1.5mm/2.0mm/2.5mm/2.7mm/3.0mm/3.5mm/4.0mm/5.0mm/6.0mm | |

| Designs | More than 500 designs(custom made designs by 3D print) | |

| Technology | Extrusion Plate+Hot stamping Film+UV coating | |

| Function | Type | Wall & Furniture cabinet&Ceiling PVC marble sheet |

| Feature | Waterproof; Fireproof; Moisture-proof; | |

| Advantage | Bendable; Wear-resisting; Sunscreen | |

| Application | Furniture cabinet, interior wall decoration such asrestaurant, hotel, supermarket, kitchen, living roomand so on. | |

| Installation | 1.Glue on the furniture cabinet or wall,2.Aluminum trim profile 3. Sealant installation | |

| Service | Certification | ISO9001, CE, SGS |

| Sample | Free samples available | |

| Min Order | 100 PCS | |

| Packing | Wooden pallet + corner protection + metal strap. | |

| Delivery Time | Shipped in 5-15 days after payment |