DEGE WPC wall panels can be used for commercial and home External use, suitable for new or refurbished building walls. As a new type of wall decoration material, with its unique waterproof function, similar color to wood products, simple installation and maintenance, it is slowly being accepted by the market as a substitute for wood products. Our wall panels are made of a unique combination of recycled wood and plastic, which combines the traditional appearance of wood with the durability of engineered composite materials, and is environmentally friendly and recyclable. This is also a popular trend in the world. Common exterior wall panels include fiber cement panels, aluminum-plastic panels, PVC panels, and stone materials. Similarity 1. Good decoration Fiber cement board, wood, and stone are natural colors, which are relatively natural and simple. WPC boards and metal boards are designed with patterns such as wood grains, and the colors of the hanging boards are rich. 2. Wide range of application: They are resistant to severe cold and heat, durable, anti-ultraviolet and anti-aging. It has good corrosion resistance to acid, alkali, salt and humid areas. No pollution, recyclable; good environmental performance. It is easy to clean and eliminates post-maintenance. 3. Fire performance: Stone has the highest fire performance, fiber cement board is A1 grade, followed by PVC exterior wall hanging board; oxygen index is 40, flame retardant and self-extinguishing from the fire; it meets the national fire protection standard B1 (GB-T8627-99), while metal The exterior wall siding is grade B2, and the wooden exterior wall siding needs to be painted with fire-resistant paint to meet the fire protection requirements. 4. High energy saving: The inner side of the WPC external wall hanging board can be very convenient to install polystyrene foam and other thermal insulation materials, so that the external wall thermal insulation effect is better. The thermal insulation material is like putting a layer of "cotton" on the house, while the WPC board is the "coat" . The metal exterior wall siding is a composite integration of thermal insulation material polyurethane and metal steel plate. The thermal insulation effect is temporarily incomparable, depending on the thickness of the thermal insulation material. However, with the same thickness, polyurethane is twice as effective as benzene board. 5. Partial waterproof: WPC exterior wall panels are connected by locking and hanging, which can play the role of partial waterproofing. The metal hanging panels are the same. 6. Easy to install and low price: All are dry construction; easy to install and firm and reliable. The decoration project with external wall hanging board is the most labor-saving decoration scheme. If there is partial damage, you only need to replace the new hanging plate in this part, which is simple, quick and convenient to maintain. 7. Long service life: Stone has the longest life span, fiber cement board is more than 50 years, anti-corrosion wood is more than 30 years, WPC exterior wall board has a service life of at least 25 years, and the surface is double-layer co-extrusion with Geloy added. The product service life is more than 30 years. If fluorocarbon paint is used for the siding, it can last for more than 15 years.

DEGE WPC wall panels can be used for commercial and home External use, suitable for new or refurbished building walls. As a new type of wall decoration material, with its unique waterproof function, similar color to wood products, simple installation and maintenance, it is slowly being accepted by the market as a substitute for wood products. Our wall panels are made of a unique combination of recycled wood and plastic, which combines the traditional appearance of wood with the durability of engineered composite materials, and is environmentally friendly and recyclable. This is also a popular trend in the world. Common exterior wall panels include fiber cement panels, aluminum-plastic panels, PVC panels, and stone materials. Similarity 1. Good decoration Fiber cement board, wood, and stone are natural colors, which are relatively natural and simple. WPC boards and metal boards are designed with patterns such as wood grains, and the colors of the hanging boards are rich. 2. Wide range of application: They are resistant to severe cold and heat, durable, anti-ultraviolet and anti-aging. It has good corrosion resistance to acid, alkali, salt and humid areas. No pollution, recyclable; good environmental performance. It is easy to clean and eliminates post-maintenance. 3. Fire performance: Stone has the highest fire performance, fiber cement board is A1 grade, followed by PVC exterior wall hanging board; oxygen index is 40, flame retardant and self-extinguishing from the fire; it meets the national fire protection standard B1 (GB-T8627-99), while metal The exterior wall siding is grade B2, and the wooden exterior wall siding needs to be painted with fire-resistant paint to meet the fire protection requirements. 4. High energy saving: The inner side of the WPC external wall hanging board can be very convenient to install polystyrene foam and other thermal insulation materials, so that the external wall thermal insulation effect is better. The thermal insulation material is like putting a layer of "cotton" on the house, while the WPC board is the "coat" . The metal exterior wall siding is a composite integration of thermal insulation material polyurethane and metal steel plate. The thermal insulation effect is temporarily incomparable, depending on the thickness of the thermal insulation material. However, with the same thickness, polyurethane is twice as effective as benzene board. 5. Partial waterproof: WPC exterior wall panels are connected by locking and hanging, which can play the role of partial waterproofing. The metal hanging panels are the same. 6. Easy to install and low price: All are dry construction; easy to install and firm and reliable. The decoration project with external wall hanging board is the most labor-saving decoration scheme. If there is partial damage, you only need to replace the new hanging plate in this part, which is simple, quick and convenient to maintain. 7. Long service life: Stone has the longest life span, fiber cement board is more than 50 years, anti-corrosion wood is more than 30 years, WPC exterior wall board has a service life of at least 25 years, and the surface is double-layer co-extrusion with Geloy added. The product service life is more than 30 years. If fluorocarbon paint is used for the siding, it can last for more than 15 years.

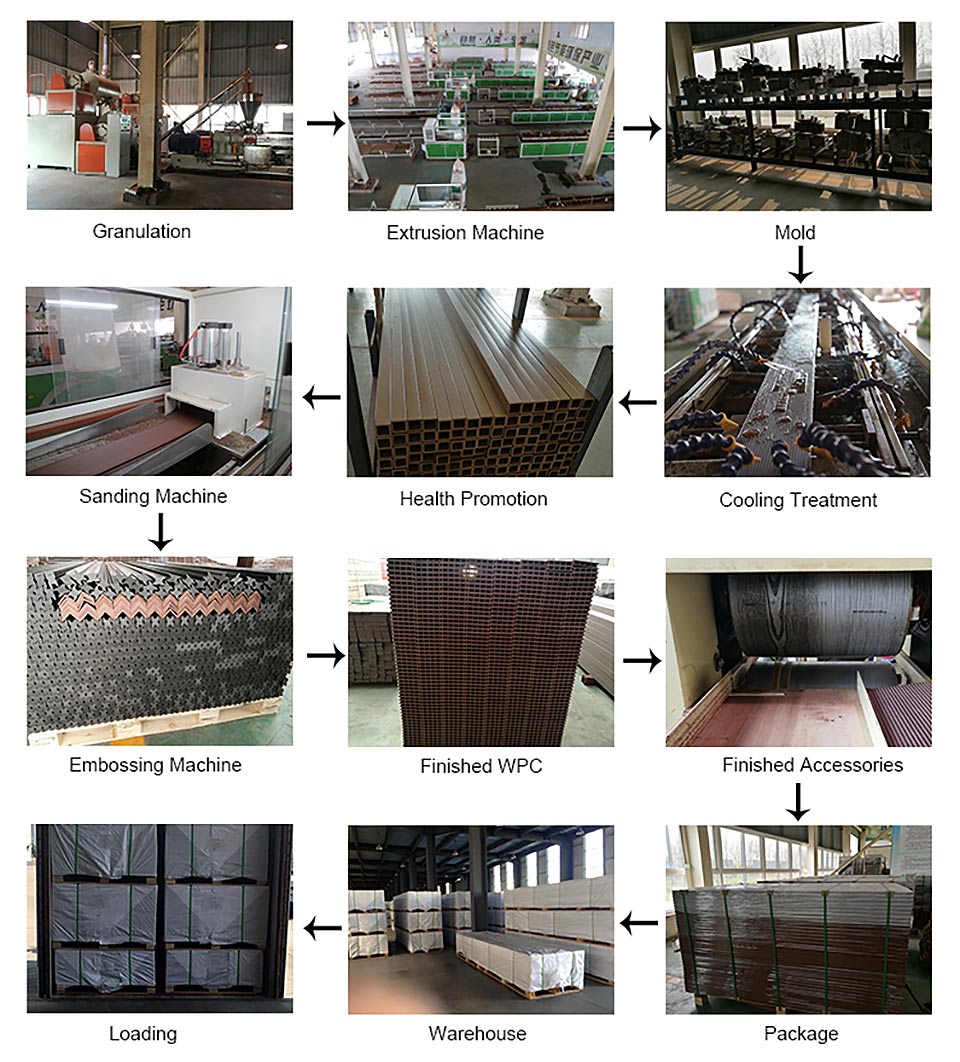

A. PE plastic wood is currently the most widely used type of plastic wood in the world, that is, our WPC CLADDING, WPC FENCING. First of all, let’s understand the raw materials of PE plastic wood products. The main raw materials are PE plastic and poplar wood powder. , Toner, anti-ultraviolet absorber, compatibilizer. 1. PE plastic: Comprehensive comparison of cost and fusion HDPE is the best choice, and the plastic wood in the market basically uses recycled materials as the main raw material, which reduces white pollution and makes our environment more healthy and environmentally friendly. "Recycled" is also called recycled plastic material. All industrially recyclable plastics that can be reused through a certain processing process are called recycled plastics; recycled materials are divided into many grades, such as special grade recycled materials and first grade recycled materials. , Secondary recycling, tertiary recycling or even garbage, it is easy to understand the meaning literally, the higher the grade, the less the impurity content of the plastic, the garbage is naturally high in the impurity content, and the choice of raw materials directly affects the choice of plastic wood Because plastic-wood material is a state where wood powder is wrapped with plastic, if the impurity content of plastic is high, and the proportion of plastic itself is small, it is naturally not able to wrap wood powder well. 2. Wood flour: In order to achieve the perfect fusion of wood flour and plastic in plastic wood, there are not only strict requirements on plastics, but also wood flour: the finer the wood flour of the same weight, the larger the surface area of the powder. The higher the proportion of plastic required; on the contrary, the larger the wood powder powder, the smaller the surface area of the powder, and the lower the proportion of plastic required during plastic fusion. After many years of experiments, poplar wood powder is the best wood powder powder, and the particle size of the powder is the best in the thickness of 80-100 mesh; the powder is too fine, the processing cost is high, the plastic composition requires more, and the cost is higher, but The molded plastic-wood product has too high plasticity; if the powder is too rough, the processing cost is low, and the plastic composition requirements are less, but the molded plastic-wood product has insufficient fusion, is brittle, and is easy to crack. 3. Auxiliary materials: The main function of toner is to match the color of plastic wood materials. At present, the main application of PE plastic wood is inorganic color powder. It has better anti-fading performance for outdoor use, which is different from the organic color used for indoor PVC ecological wood. Powder, organic toner color is more vivid and bright. The main function of the anti-ultraviolet absorber is to improve the anti-ultraviolet ability of the plastic wood outdoor use, and improve the anti-aging performance. Compatibilizer is an additive that promotes compatibility between wood flour and resin. B. Understand the raw materials of plastic wood briefly, the next step is to pelletize. According to the above raw materials, mix according to a certain ratio, extrude plastic wood pellets through high temperature fusion drying, and pack them for use. The main function of the pelletizing equipment is to realize the pre-plasticization process of wood powder and plastic, realize uniform mixing of biomass powder material and PE plastic under melting conditions, and conduct pretreatment for the production of plastic wood materials. Due to the poor fluidity of wood-plastic melt, the design of wood-plastic material pelletizer and plastic pelletizer is not exactly the same. For different plastics, the design of the pelletizer is also different. The pelletizer usually used for polyethylene usually uses a conical twin-screw extruder, because polyethylene is a heat-sensitive resin, and the conical twin-screw extruder has strong shearing force and the screw lengths are relatively parallel. The twin screw extruder is short, which reduces the residence time of the material in the barrel. The outer diameter of the screw has a conical design from large to small, so the compression ratio is quite large, and the material can be plasticized more fully and uniformly in the barrel. C. After pelletizing, it enters the extrusion stage. Several preparations need to be done before extrusion: 1. Make sure that there are no impurities or particles of other colors remaining in the hopper to avoid impure color of the plastic wood produced; 2. Check whether the vacuum equipment of the extruder is unobstructed and ensure that the vacuum degree is not less than -0.08mpa. The vacuum barrel should be cleaned twice per shift if it is normal. Do not use metal tools to clean the exhaust holes, and use plastic or wooden sticks to clean up the impurities in the exhaust holes of the barrel; 3. Check whether the hopper is equipped with a metal filter. The particles are filtered through metal to remove the metal impurities mixed in the particles, reduce the wear of the metal impurities on the inside of the equipment and ensure the perfect fusion of the molded plastic-wood profiles. 4. Whether the cooling water system is operating normally. A perfect cooling water system is the necessary equipment for cooling after plastic-wood extrusion. Timely cooling treatment can ensure the good shape of plastic-wood profiles. 5. Install plastic-wood molds, and install designated molds according to the profiles to be produced. 6. Check whether the pneumatic cutting machine and other screw components can operate normally. D. The temperature of the newly extruded plastic-wood profile is relatively high, and it needs to be manually placed on a flat ground. After the profile is completely cooled, it will be processed and packaged. Although this step is simple, it is very important. If the factory ignores these details, the factory materials will often have defects. Uneven plastic wood will easily lead to different thicknesses of the upper and lower surfaces of the product after the later grinding and processing. In addition, uneven profiles will bring certain difficulties to the construction and affect the landscape effect. E. According to the needs of customers, process the plastic-wood profiles: 1. Grinding treatment is to remove a layer of plastic skin produced when the plastic-wood profile is extruded, so that the plastic-wood profile has better wear resistance when installed at the factory. 2. Embossing treatment: After the surface of the profile is polished, the plastic-wood is embossed to make the surface of the plastic-wood profile have a wood-like effect. 3. Cutting, tenoning processing, customized size according to customer needs, and customized products such as tenoning needs. 4. After the above processing is completed, the last step is to package the product. Reasonable packaging of the product can reduce the damage caused by the product during delivery.

A. PE plastic wood is currently the most widely used type of plastic wood in the world, that is, our WPC CLADDING, WPC FENCING. First of all, let’s understand the raw materials of PE plastic wood products. The main raw materials are PE plastic and poplar wood powder. , Toner, anti-ultraviolet absorber, compatibilizer. 1. PE plastic: Comprehensive comparison of cost and fusion HDPE is the best choice, and the plastic wood in the market basically uses recycled materials as the main raw material, which reduces white pollution and makes our environment more healthy and environmentally friendly. "Recycled" is also called recycled plastic material. All industrially recyclable plastics that can be reused through a certain processing process are called recycled plastics; recycled materials are divided into many grades, such as special grade recycled materials and first grade recycled materials. , Secondary recycling, tertiary recycling or even garbage, it is easy to understand the meaning literally, the higher the grade, the less the impurity content of the plastic, the garbage is naturally high in the impurity content, and the choice of raw materials directly affects the choice of plastic wood Because plastic-wood material is a state where wood powder is wrapped with plastic, if the impurity content of plastic is high, and the proportion of plastic itself is small, it is naturally not able to wrap wood powder well. 2. Wood flour: In order to achieve the perfect fusion of wood flour and plastic in plastic wood, there are not only strict requirements on plastics, but also wood flour: the finer the wood flour of the same weight, the larger the surface area of the powder. The higher the proportion of plastic required; on the contrary, the larger the wood powder powder, the smaller the surface area of the powder, and the lower the proportion of plastic required during plastic fusion. After many years of experiments, poplar wood powder is the best wood powder powder, and the particle size of the powder is the best in the thickness of 80-100 mesh; the powder is too fine, the processing cost is high, the plastic composition requires more, and the cost is higher, but The molded plastic-wood product has too high plasticity; if the powder is too rough, the processing cost is low, and the plastic composition requirements are less, but the molded plastic-wood product has insufficient fusion, is brittle, and is easy to crack. 3. Auxiliary materials: The main function of toner is to match the color of plastic wood materials. At present, the main application of PE plastic wood is inorganic color powder. It has better anti-fading performance for outdoor use, which is different from the organic color used for indoor PVC ecological wood. Powder, organic toner color is more vivid and bright. The main function of the anti-ultraviolet absorber is to improve the anti-ultraviolet ability of the plastic wood outdoor use, and improve the anti-aging performance. Compatibilizer is an additive that promotes compatibility between wood flour and resin. B. Understand the raw materials of plastic wood briefly, the next step is to pelletize. According to the above raw materials, mix according to a certain ratio, extrude plastic wood pellets through high temperature fusion drying, and pack them for use. The main function of the pelletizing equipment is to realize the pre-plasticization process of wood powder and plastic, realize uniform mixing of biomass powder material and PE plastic under melting conditions, and conduct pretreatment for the production of plastic wood materials. Due to the poor fluidity of wood-plastic melt, the design of wood-plastic material pelletizer and plastic pelletizer is not exactly the same. For different plastics, the design of the pelletizer is also different. The pelletizer usually used for polyethylene usually uses a conical twin-screw extruder, because polyethylene is a heat-sensitive resin, and the conical twin-screw extruder has strong shearing force and the screw lengths are relatively parallel. The twin screw extruder is short, which reduces the residence time of the material in the barrel. The outer diameter of the screw has a conical design from large to small, so the compression ratio is quite large, and the material can be plasticized more fully and uniformly in the barrel. C. After pelletizing, it enters the extrusion stage. Several preparations need to be done before extrusion: 1. Make sure that there are no impurities or particles of other colors remaining in the hopper to avoid impure color of the plastic wood produced; 2. Check whether the vacuum equipment of the extruder is unobstructed and ensure that the vacuum degree is not less than -0.08mpa. The vacuum barrel should be cleaned twice per shift if it is normal. Do not use metal tools to clean the exhaust holes, and use plastic or wooden sticks to clean up the impurities in the exhaust holes of the barrel; 3. Check whether the hopper is equipped with a metal filter. The particles are filtered through metal to remove the metal impurities mixed in the particles, reduce the wear of the metal impurities on the inside of the equipment and ensure the perfect fusion of the molded plastic-wood profiles. 4. Whether the cooling water system is operating normally. A perfect cooling water system is the necessary equipment for cooling after plastic-wood extrusion. Timely cooling treatment can ensure the good shape of plastic-wood profiles. 5. Install plastic-wood molds, and install designated molds according to the profiles to be produced. 6. Check whether the pneumatic cutting machine and other screw components can operate normally. D. The temperature of the newly extruded plastic-wood profile is relatively high, and it needs to be manually placed on a flat ground. After the profile is completely cooled, it will be processed and packaged. Although this step is simple, it is very important. If the factory ignores these details, the factory materials will often have defects. Uneven plastic wood will easily lead to different thicknesses of the upper and lower surfaces of the product after the later grinding and processing. In addition, uneven profiles will bring certain difficulties to the construction and affect the landscape effect. E. According to the needs of customers, process the plastic-wood profiles: 1. Grinding treatment is to remove a layer of plastic skin produced when the plastic-wood profile is extruded, so that the plastic-wood profile has better wear resistance when installed at the factory. 2. Embossing treatment: After the surface of the profile is polished, the plastic-wood is embossed to make the surface of the plastic-wood profile have a wood-like effect. 3. Cutting, tenoning processing, customized size according to customer needs, and customized products such as tenoning needs. 4. After the above processing is completed, the last step is to package the product. Reasonable packaging of the product can reduce the damage caused by the product during delivery.

| Brand | DEGE |

| Name | WPC WALL CLADDING |

| Item | CLADDING |

| Standard size | |

| WPC component | 30% HDPE+60% wood fiber + 10% additives |

| Accessories | Patented clip-easy system |

| Delivery time | About 20-25 days for one 20'ft container |

| Payment | 30% deposited, the rest should be paid before deliver |

| Maintenance | Free maintenance |

| Recycling | 100% recyclable |

| Package | Pallet or bulk packing |