| SPC Flooring Specification | |

| Code | 1171L |

| Thickness | 3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

| Wear Layer | 0.2mm, 0.3mm, 0.5mm |

| Size | 910*148mm, 1220*178mm, 1500*228mm, 1800*228mm, etc. |

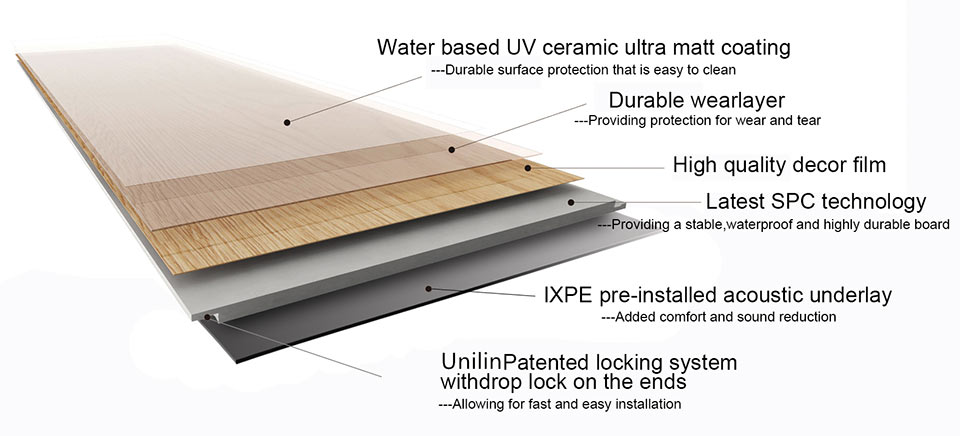

| Surface | Crystal, Light/Deep Embossed, Real Wood, Handscraped |

| Core Material | 100% virgin material |

| Click System | Unilin Click, Drop Lock(I4F) |

| Special treatment | V-Groove, Soundproof EVA/IXPE |

| Installation Method | Floating |

IXPE Backing

Plain EVA Backing

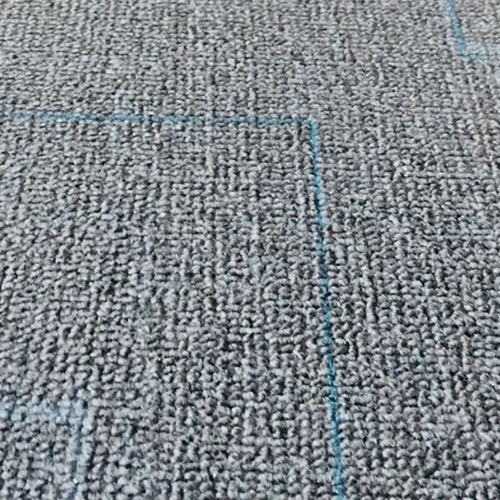

Carpet Surface

Crystal Surface

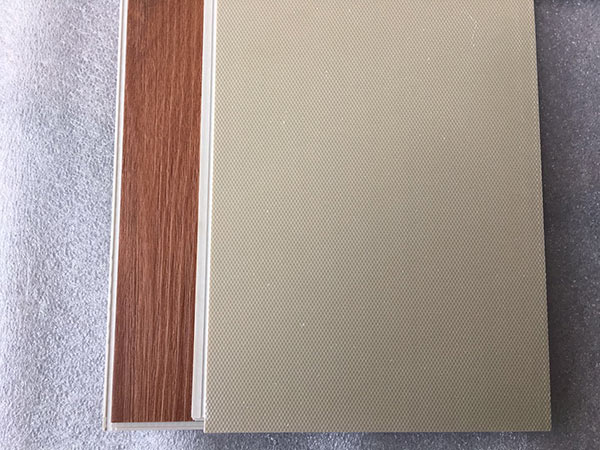

Handscraped Spc Flooring

9 Laboratory

SPC Floor Fireproof Test

SPC Floor Waterproof Test

Deep Embossed Surface

Leather Surface

Light Embossed

Marble Surface

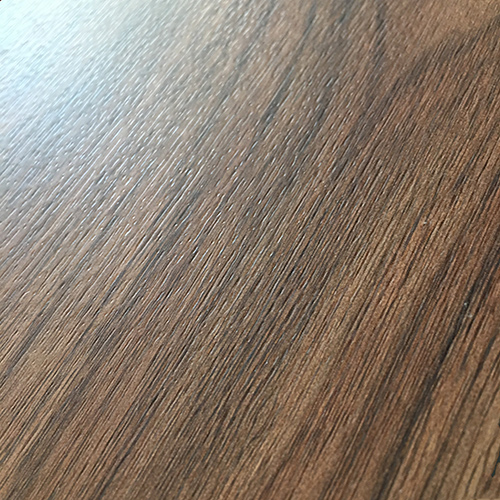

Real Wood

SPC Floor Anti-scracth Test

4 SPC Health Board

5 SPC Quality Test

1 Workshop

2 SPC Coextrusion Machine

3 UV Machine

10 Warehouse

7 SPC Click Macking Machine

11 Loading

8 Foam Adding Machine

6 SPC Cutting Machine/strong>

| SPC Floor Packing List | |||||||||

| Size | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | pallet/20ft | sqm/20ft | ctns/20ft | Cargo Weight/20ft |

| 910×148*3.8mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn/12pallet, 70ctn/12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910×148*4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn/6pallet, 70ctn/18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680 | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680 | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn/10pallet, 78ctn/10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440 | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10pallet, 84ctn/10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*300*4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn/6pallet, 78ctn/14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500*225*5mm+2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800*225*5mm+1.5mm IXPE | 0.4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Remarks: The quantity per container can be adjusted according to the limited weight of container for different port. | |||||||||

V Groove Painted

Micro V-Groove Beveled

Unilin Click 1

Unilin Click 2

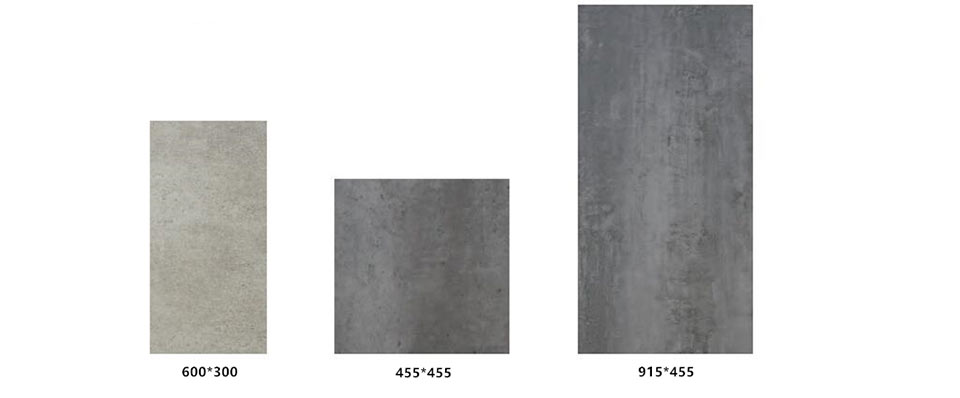

SPC VINYL PLANK FLOORING, as the representative of the third-generation PLASTICK FLOORING floor paving materials, is slowly entering home improvement from engineering projects. Compared with the first generation of stone floor paving materials, such as Marble and Cement. Compared with the second-generation wooden floor covering materials, such as hardwood flooring, engineering wooden flooring, laminate flooring and bamboo flooring and so on, it has unique advantages, such as waterproof, non-slip and abrasion resistance. Now, SPC VINYL PLANK FLOORING is produced in 4 main regions all over the world East Asia: South Korea's LG, Hanwha, Japan's Lonseal, Takilon and other brands, the main products are coiled pvc flooring. United States: Armstrong, Roppe and other brands. Europe: Tarkett in France, Nora in Germany, Polyflor in the UK, Grabo in Hungary, etc. China: YIHUA in Suzhou, DAJULONG in Shanghai, PROLONG in Taiwan, etc.The application of SPC flooring is very wide, such as indoor homes, hospitals, schools, office buildings, factories, public places, supermarkets, commerce, sports venues and other places. Education system (including schools, training centers, kindergartens, etc.) Medical system (including hospitals, laboratories, pharmaceutical factories, nursing homes, etc.) Commercial systems (including shopping malls, supermarkets, hotels, entertainment and leisure centers, restaurants, specialty stores, etc.) Sports system (sports venues, activity centers, etc.) Office system (office building, meeting room, etc.) Industrial systems (factory buildings, warehouses, etc.) Transportation system (airport, railway station, bus station, terminal, etc.) Home system (home interior living room, bedroom, kitchen, balcony, study, etc.)1. VINYL PLANK FLOORING has composite and homogenous floors. The composite VINYL PLANK FLOORING has a wear-resistant layer on the surface. There are professional personnel in shopping malls, so it is better to choose composite stone plastic flooring. The wear resistance of the homogeneous VINYL FLOORING is not good and it is not suitable for school use. 2. Because school students are active, tables, chairs and benches move frequently, and the impact on the floor is also great. Therefore, the floor must have high abrasion resistance, good abrasion resistance, easy to clean and replace, environmentally friendly floors, and colorful stone plastics. The floor works. Floors with a size of about 450*450mm or 600*300mm are better, and the thickness of the wear-resistant layer is more than 0.5mm; the thickness of the floor is 3.0-5mm. 3. The SPC is made of PVC (polyvinyl chloride resin), stone powder, additives, etc. through high temperature calendering, and the surface is added with a wear-resistant layer. It is impossible to contain harmful substances such as formaldehyde. It is 100% formaldehyde-free environmental protection floor .

SPC VINYL PLANK FLOORING, as the representative of the third-generation PLASTICK FLOORING floor paving materials, is slowly entering home improvement from engineering projects. Compared with the first generation of stone floor paving materials, such as Marble and Cement. Compared with the second-generation wooden floor covering materials, such as hardwood flooring, engineering wooden flooring, laminate flooring and bamboo flooring and so on, it has unique advantages, such as waterproof, non-slip and abrasion resistance. Now, SPC VINYL PLANK FLOORING is produced in 4 main regions all over the world East Asia: South Korea's LG, Hanwha, Japan's Lonseal, Takilon and other brands, the main products are coiled pvc flooring. United States: Armstrong, Roppe and other brands. Europe: Tarkett in France, Nora in Germany, Polyflor in the UK, Grabo in Hungary, etc. China: YIHUA in Suzhou, DAJULONG in Shanghai, PROLONG in Taiwan, etc.The application of SPC flooring is very wide, such as indoor homes, hospitals, schools, office buildings, factories, public places, supermarkets, commerce, sports venues and other places. Education system (including schools, training centers, kindergartens, etc.) Medical system (including hospitals, laboratories, pharmaceutical factories, nursing homes, etc.) Commercial systems (including shopping malls, supermarkets, hotels, entertainment and leisure centers, restaurants, specialty stores, etc.) Sports system (sports venues, activity centers, etc.) Office system (office building, meeting room, etc.) Industrial systems (factory buildings, warehouses, etc.) Transportation system (airport, railway station, bus station, terminal, etc.) Home system (home interior living room, bedroom, kitchen, balcony, study, etc.)1. VINYL PLANK FLOORING has composite and homogenous floors. The composite VINYL PLANK FLOORING has a wear-resistant layer on the surface. There are professional personnel in shopping malls, so it is better to choose composite stone plastic flooring. The wear resistance of the homogeneous VINYL FLOORING is not good and it is not suitable for school use. 2. Because school students are active, tables, chairs and benches move frequently, and the impact on the floor is also great. Therefore, the floor must have high abrasion resistance, good abrasion resistance, easy to clean and replace, environmentally friendly floors, and colorful stone plastics. The floor works. Floors with a size of about 450*450mm or 600*300mm are better, and the thickness of the wear-resistant layer is more than 0.5mm; the thickness of the floor is 3.0-5mm. 3. The SPC is made of PVC (polyvinyl chloride resin), stone powder, additives, etc. through high temperature calendering, and the surface is added with a wear-resistant layer. It is impossible to contain harmful substances such as formaldehyde. It is 100% formaldehyde-free environmental protection floor .