| Type | Size | Package | NO Pallet/20FCL | Pallet/20FCL | Size of Box | G.W. | N.W. |

| Carbonized Bamboo | 1020*130*15mm | 20pcs/ctn | 660 ctns/1750.32 sqm | 10 plt, 52ctns/plt,520ctns/1379.04 sqms | 1040*280*165 | 28kgs | 27kgs |

| 1020*130*17mm | 18pcs/ctn | 640 ctns/1575.29 sqm | 10 plt, 52ctns/plt,520ctns/1241.14 sqms | 1040*280*165 | 28kgs | 27kgs | |

| 960*96*15mm | 27pcs/ctn | 710 ctns/ 1766.71 sqm | 9 plt, 56ctns/plt,504ctns/1254.10 sqms | 980*305*145 | 26kgs | 25kgs | |

| 960*96*10mm | 39pcs/ctn | 710 ctns/ 2551.91 sqm | 9 plt, 56ctns/plt,504ctns/1810.57 sqms | 980*305*145 | 25kgs | 24kgs | |

| Strand Woven Bamboo | 1850*125*14mm | 8pcs/ctn | 672 ctn, 1243.2sqm | 970*285*175 | 29 kg | 28 kg | |

| 960*96*15mm | 24pcs/ctn | 560 ctn, 1238.63sqm | 980*305*145 | 26 kg | 25 kg | ||

| 950*136*17mm | 18pcs/ctn | 672ctn, 1562.80sqm | 970*285*175 | 29 kg | 28kg |

Bamboo T&G -Bamboo Florinig

drop Bamboo Florinig

T&G LOCK BAMBOO-Bamboo Florinig

unilin Bamboo Florinig

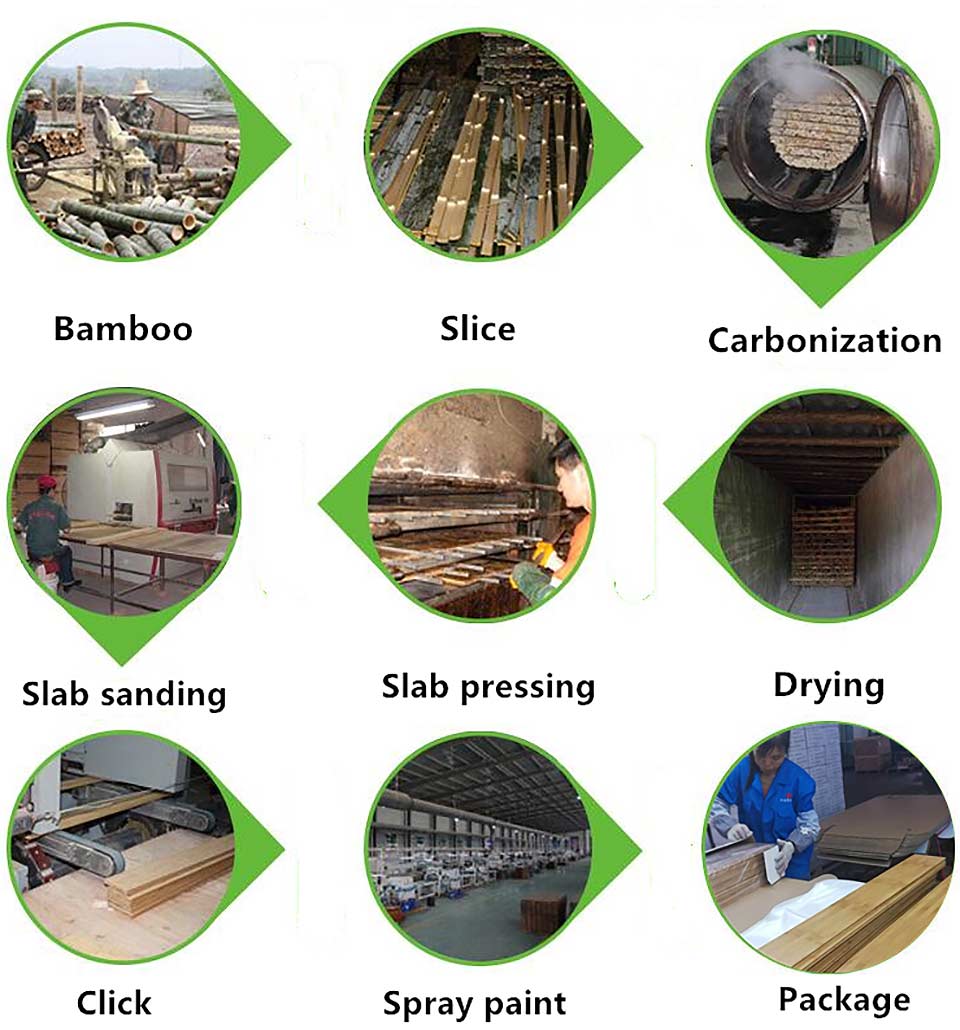

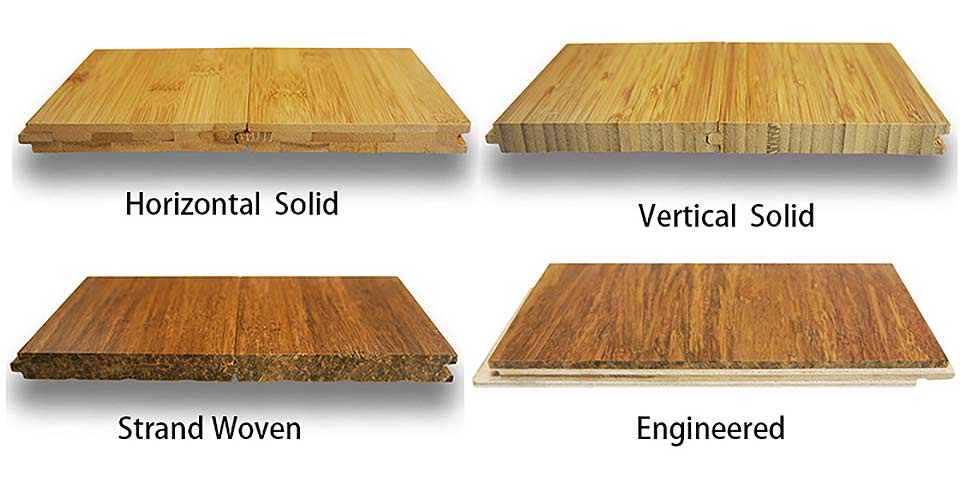

Horizontal Bamboo Floor is a new type of building decoration material. It uses natural high-quality bamboo as raw material. After more than 20 processes, the bamboo puree juice is removed, pressed by high temperature and high pressure, and then through multiple layers of paint, and finally dried by infrared rays. . Bamboo flooring brings a green and fresh wind to the building materials market with its natural advantages and many excellent properties after molding. The bamboo floor has the natural texture of bamboo, fresh and elegant, giving people a return to nature, elegant and refined feeling. It has many characteristics. First of all, bamboo flooring uses bamboo instead of wood, which has the original characteristics of wood. In the process of bamboo processing, high-quality glue that meets national standards is used to avoid the harm of formaldehyde and other substances to the human body. Using advanced equipment and technology, through 26 processes of processing the raw bamboo, it has the natural beauty of the raw wood floor and the durability of ceramic floor tiles. Horizontal Bamboo is not a new product. It has appeared in the late 1980s in China. Since 1998, bamboo flooring manufacturing technology has matured. At that time, the output was only 300,000 square meters. Because the technology at that time was more complex and not mature enough, the use of bamboo flooring There is no better solution to the problems of longevity, moisture and moth prevention, so it has not been further developed and popularized. In the 21st world, due to technological breakthroughs, bamboo flooring has explosively entered the market. The processing technology of bamboo flooring is different from that of traditional bamboo products. It is made of middle-to-high-grade bamboo, which is processed through strict selection, material making, bleaching, vulcanization, dehydration, insect control, and corrosion protection. It is formed by high temperature and high pressure thermosetting glued surface. Relatively solid wood flooring. It has its advantages and disadvantages. Bamboo and wood floors are wear-resistant, pressure-resistant, moisture-proof, and fire-resistant. Its physical properties are better than solid wood floors. The tensile strength is higher than solid wood floors and the shrinkage rate is lower than solid wood floors. Therefore, it will not crack after laying. No distortion, no deformation and arching. However, bamboo and wood flooring has high strength and hardness, and the foot feel is not as comfortable as solid wood flooring, and the appearance is not as diverse as solid wood flooring. Its appearance is natural bamboo texture, beautiful color, and conforms to people's mentality of returning to nature, which is better than composite wood flooring. Therefore, the price is also between solid wood flooring and composite wood flooring.

Horizontal Bamboo Floor is a new type of building decoration material. It uses natural high-quality bamboo as raw material. After more than 20 processes, the bamboo puree juice is removed, pressed by high temperature and high pressure, and then through multiple layers of paint, and finally dried by infrared rays. . Bamboo flooring brings a green and fresh wind to the building materials market with its natural advantages and many excellent properties after molding. The bamboo floor has the natural texture of bamboo, fresh and elegant, giving people a return to nature, elegant and refined feeling. It has many characteristics. First of all, bamboo flooring uses bamboo instead of wood, which has the original characteristics of wood. In the process of bamboo processing, high-quality glue that meets national standards is used to avoid the harm of formaldehyde and other substances to the human body. Using advanced equipment and technology, through 26 processes of processing the raw bamboo, it has the natural beauty of the raw wood floor and the durability of ceramic floor tiles. Horizontal Bamboo is not a new product. It has appeared in the late 1980s in China. Since 1998, bamboo flooring manufacturing technology has matured. At that time, the output was only 300,000 square meters. Because the technology at that time was more complex and not mature enough, the use of bamboo flooring There is no better solution to the problems of longevity, moisture and moth prevention, so it has not been further developed and popularized. In the 21st world, due to technological breakthroughs, bamboo flooring has explosively entered the market. The processing technology of bamboo flooring is different from that of traditional bamboo products. It is made of middle-to-high-grade bamboo, which is processed through strict selection, material making, bleaching, vulcanization, dehydration, insect control, and corrosion protection. It is formed by high temperature and high pressure thermosetting glued surface. Relatively solid wood flooring. It has its advantages and disadvantages. Bamboo and wood floors are wear-resistant, pressure-resistant, moisture-proof, and fire-resistant. Its physical properties are better than solid wood floors. The tensile strength is higher than solid wood floors and the shrinkage rate is lower than solid wood floors. Therefore, it will not crack after laying. No distortion, no deformation and arching. However, bamboo and wood flooring has high strength and hardness, and the foot feel is not as comfortable as solid wood flooring, and the appearance is not as diverse as solid wood flooring. Its appearance is natural bamboo texture, beautiful color, and conforms to people's mentality of returning to nature, which is better than composite wood flooring. Therefore, the price is also between solid wood flooring and composite wood flooring.

| 1) Materials: | 100% Raw Bamboo |

| 2) Colors: | Strand Woven |

| 3) Size: | 1840*126*14mm / 960*96*15mm |

| 4) Moisture content: | 8%-12% |

| 5) Formaldehyde emission: | Up to E1 standard of Europe |

| 6) Varnish: | Treffert |

| 7) Glue: | Dynea |

| 8) Glossiness: | Matt, Semi gloss |

| 9) Joint: | Tongue & Groove (T& G) click ; Unilin+Drop click |

| 10) Supply ability: | 110,000m2 / month |

| 11) Certificate: | CE Certification , ISO 9001:2008, ISO 14001:2004 |

| 12) Packing: | Plastic films with carton box |

| 13) Delivery Time: | Within 25 days after received advance payment |